Record Store Day 2016 – How A Record is Made

This Saturday 04/16/2016 is Record Store Day, and we’re stoked. Like pencils, records are part of the analog world where every action has an tangible, visible or audible reaction. I’ve collected records since I was a kid going to punk shows in veterans halls, but I’ve never stopped to think about the nuances of their production. So, I did a bit of digging and came up with a Cliff Notes version of record manufacturing.

History

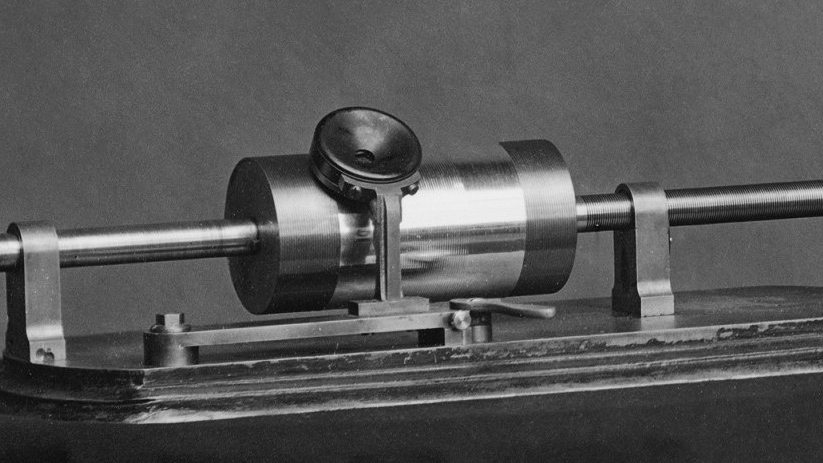

To learn how records are made, we need to go back to the beginning. In 1877, Thomas Edison invented the phonograph, a cylindrical tube of tin that captured sound waves in the form of grooves and deviations in the surface of the metal. As a stylus (or needle) was drug across these deviations, the stylus vibrated, creating a faint reproduction of the recorded sound. This is analog music reproduction in its most basic form: creating deviations in the surface of a material and dragging a stylus over the deviations to produce a sound.

Fast forward 130 years, and vinyl records are still being produced using a very similar system.

Master Disc / Lacquer Cutting

The first step of the manufacturing process is cutting a master disc or lacquer. This disc is physically cut by a grooving machine that receives the audio signal from the digital master audio file. This is a very hands on, artisanal process, and it takes a well-trained eye and ear to detect the nuances of the grooved audio. In fact, when we were producing our first record, we learned that there are only a handful of lacquer cutting masters still practicing their craft today.

Metal Plating

Once the lacquer is finished, it is then metal plated to create what is known as “the matrix.” Silver is was used for the initial plating, followed by a layer of copper, nickel and/or steel to provide structural support. Once the plating has hardened, the lacquer is removed (sometimes being destroyed in the process), leaving behind a metal negative of the recorded sound.

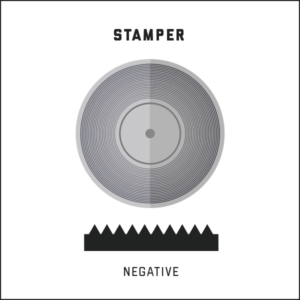

The Mother & The Stamper

This metal negative is then pressed into another piece of malleable metal to create a metal record known as “the mother.” The mother resembles the vinyl records you have on your shelf, only quite a bit thicker and heavier. This mother disc is then plated using the same techniques used previously to produce what is known as “the stamper.” Since mother discs are made of metal, they are very durable, and can be used to create multiple stampers over their lifetime.

Test Presses

With the stamper in hand, the actual record pressing begins (fun fact, record production is called “pressing” because the stamper is physically pressed into the soft vinyl to create the finished record). Before mass production begins, test presses are produced and sent to the artist/label to ensure they are pleased with the sound quality.

For many record collectors, test presses represent the holy grail of any given release. Since there are only a handful made for each album, they are incredibly rare. In our case, six test presses were made during the production of Knuckleball Prime. Once the test presses have been approved mass production can begin.

Production

At this stage of the process, the stamper is used to press the final product. Labels are applied, the vinyl is sleeved and the finished records are shipped to the label.

In honor of Record Store Day 2016, every physical copy of Knuckleball Prime sold on 04/16/2016 will be signed by Willy Tea Taylor himself, and will include a Blackwing pencil. Head over to BlackwingMusic.com to grab your autographed copy of the album.