Creating the Blackwing Point Guard

Last week, we launched the Blackwing Point Guard, a point protector designed specifically for Blackwing pencils. This is an item we’ve been working on for nearly two full years, and one I didn’t think would ever see the light of day. It was a deceptively challenging project, but it was an enlightening one as well.

The origin of the Point Guard dates back to early 2015, when we designed the prototype unit with the help of Jon Fontane at Metal Shop CT. If you aren’t already familiar with his work, Jon is the creative mind behind the Twist Bullet Pencil, a modern take on the bullet pencils popularized in the early to mid 20th century. Jon helped us come up with the design of the unit and its overall functionality, and he was a blast to work with.

After a few months of back and forth, we decided to mutually part ways on the project. Jon was busy building his own successful brand, and we shifted our focus to the Volumes program and a few of the other items we had in the works. I thought the Point Guard project was dead in the water, and I cherished the few prototype samples we had at our HQ like rare artifacts.

That’s how the project stayed for months until, while working on another project, I met an aluminum worker from Taiwan. He saw the Point Guard prototype I kept with my notebook, and told me he could make them for us. I was beyond stoked, so we started working on a production sample right away.

If this project taught me one thing, it’s that tolerance variances are REAL. The diameter of our pencils (from flat face to flat face) range from 7.15mm on a pencil with very little lacquer (like the Blackwing 211) to up to 7.25mm on a pencil with extensive finishing (like the Blackwing 602). 0.1mm may not sound like much, but that variability is quickly doubled when factoring in ±0.05 tolerance required by our metal partner.

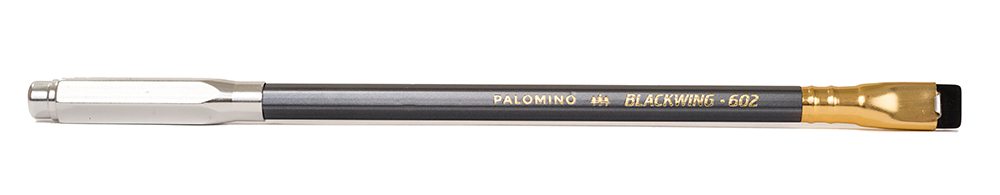

Thanks to this variability, the first round of samples we received proved to be too loose. We came up with something we called the “3 shake test” to check the security of the cap. If the cap came off after three shakes, it was no good (this was something that was going to be used on the go, after all). The first prototype passed the test when placed on a Palomino Blackwing 602, but failed miserably when used with a Palomino Blackwing. So, we adjusted interior diameter of the cap and gave it another go.

We received the second round of samples, and they passed the 3 shake test. SUCCESS! The Point Guard was ready for action.

Unlike other pencil caps, the Point Guard isn’t designed to slide over the pencil until the point meets the end of the cap. Instead, it is designed to fit snugly on the end as soon as it reaches the unsharpened portion of the pencil. This allows the Point Guard to deal with those variances we were struggling with, and also allows it to accept a wide range of sharpening lengths, from short points to expertly shaped hand-sharpenings. It also means you probably only need to push the cap about 1/4 inch up the barrel of the pencil before it’s secure.

Blackwing Volumes subscribers were gifted a Point Guard with their Blackwing 530 subscription shipment. If you’d like to subscribe and get a free Point Guard in the process, you can do that here. If you’d like to pick a Point Guard by its lonesome, you do that as well.